Fordays Gifu Manufacturing Plant

The Gifu Manufacturing Plant was established in 2017 to ensure the safety and quality of Fordays’ products. At this facility, we use pure, untainted water sourced from the surrounding pristine environment as the primary ingredient for our Natural DN Collagen. This water goes through several filtration and purification processes, including deionization resulting in pharmaceutical-grade purified water.

To prevent external contamination, production occurs in a cleanroom environment. Line workers don cleanroom suits and pass through an air shower room before entering the cleanroom.

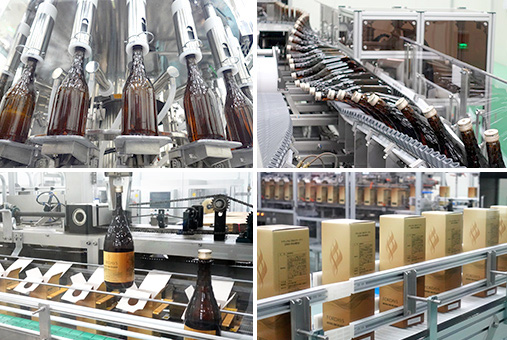

The production process includes strict quality inspections at every step which encompasses ingredient weighing, mixing, filtration, sterilization, bottling, shower sterilization, cooling, water removal, visual inspection, labeling, packaging, and shipping. The Gifu Manufacturing Plant utilizes cutting-edge technology, and the production process is fully automated following the mixing stage.

To provide our consumers with safety and assurance, the Gifu Manufacturing Plant has achieved certification under Good Manufacturing Practices and complies with international management system standards for food safety. Our products are manufactured under stringent quality control measures to maintain the highest standards. We are dedicated to continuously improving our efforts to uphold safety and deliver peace of mind.

The Gifu Manufacturing Plant Achieves FSSC 22000 Certification, an International Food Safety Management Standard

Fordays obtained the FSSC 22000 certification on October 27, 2025. FSSC 22000 (Food Safety System Certification 22000) is an international management system standard designed to ensure food safety. It is based on ISO 22000 and incorporates stricter requirements approved by the Global Food Safety Initiative (GFSI), making it a widely recognized and trusted certification in the industry.

Good Manufacturing Practice (GMP) Certification by the Japan Health and Nutrition Food Association (JHNFA)

On February 4, 2022, the Gifu Manufacturing Plant received certification for the Good Manufacturing Practice (GMP) program for dietary supplements from the Japan Health and Nutrition Food Association (JHNFA). The GMP program is designed to ensure that products are consistently produced and controlled in accordance with established quality standards throughout all stages, from the receipt of raw materials to the processes of manufacturing and shipping.

- Minimize human error throughout the manufacturing process.

- Prevent contamination and ensure the integrity of product quality.

- Implement a comprehensive quality assurance system to uphold high standards.

Gifu Prefecture HACCP Certification Achievement

On August 5, 2022, the Gifu Manufacturing Plant achieved certification as a Hazard Analysis and Critical Control Point (HACCP) facility from Gifu Prefecture. HACCP represents a systematic methodology focused on identifying and analyzing potential health hazards throughout each stage of the manufacturing process. This scientific approach to hygiene control effectively ensures product safety by establishing and managing critical control points.